With over 150 grades of SS Machine Screws, several industrial sectors prefer using about 15 grades regularly. Out of these 15 grades, the two most important grades are alloy 304 and 316. While grade 304 Stainless Steel Button Head Machine Screws are considered to be cost effective with moderate corrosion.

Their widespread availability and versatility make grade 304 Stainless Steel Csk Machine Screws the most popular alloys around. However, in terms of higher mechanical properties and moderate cost, most Stainless Steel Machine Screw Manufacturers prefer using grade 316. Marine grade or as simply known as 316 SS Machine Screws are well suited to be used for multiple applications. Apart from being used in marine based applications grade 316, Chrome Plated Stainless Steel Machine Screws offer good resistance to oxidation corrosion.

Hence the use of Imperial Stainless Steel Machine Screws in the paper industry is justified. Moreover, the Allen Head Stainless Steel Machine Screws are much tougher and harder in comparison to alloy 304. Therefore they have an extended service life, making them a high value investment across different industries. Speaking about its innumerable uses, the food and beverage industry is not to be left behind. In the food sector, the demand for hygienic constructed equipment is really high.

Since grade 316 Stainless Steel Round Head Machine Screws do not react with the chemicals present in different food and beverage groups such as acids, alkaline and neutral compounds, they are a good fit. Similarly, many manufacturers in the pharma sector prefer using the Black Oxide Stainless Steel Machine Screws to construct non-reactive equipment to produce a non-toxic, yet an effective end product i.e. – medicine.

Truss Head Machine Screws Head Dimensions

|

NOMINAL

SIZE |

A

|

H

|

J

|

T

|

M

|

G

|

N

|

PHILLIPS

DRIVER SIZE |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

HEAD

DIAMETER |

HEAD

HEIGHT |

SLOT WIDTH

|

SLOT DEPTH

|

DIMENSIONS OF RECESS

|

||||||||||

|

DIAMETER

|

DEPTH

|

WIDTH

|

||||||||||||

|

MAX

|

MIN

|

MAX

|

MIN

|

MAX

|

MIN

|

MAX

|

MIN

|

MAX

|

MIN

|

MAX

|

MIN

|

MIN

|

||

|

2

|

.194

|

.180

|

.053

|

.044

|

.031

|

.023

|

.031

|

.022

|

.104

|

.091

|

.059

|

.041

|

.018

|

1

|

|

3

|

.226

|

.211

|

.061

|

.051

|

.035

|

.027

|

.036

|

.026

|

.110

|

.097

|

.066

|

.049

|

.018

|

1

|

|

4

|

.257

|

.241

|

.069

|

.059

|

.039

|

.031

|

.040

|

.030

|

.112

|

.099

|

.069

|

.051

|

.018

|

1

|

|

5

|

.289

|

.272

|

.078

|

.066

|

.043

|

.035

|

.045

|

.034

|

.128

|

.115

|

.085

|

.067

|

.019

|

1

|

|

6

|

.321

|

.303

|

.086

|

.074

|

.048

|

.039

|

.050

|

.037

|

.158

|

.145

|

.084

|

.059

|

.027

|

2

|

|

8

|

.384

|

.364

|

.102

|

.088

|

.054

|

.045

|

.058

|

.045

|

.173

|

.160

|

.099

|

.074

|

.029

|

2

|

|

10

|

.448

|

.425

|

.118

|

.103

|

.060

|

.050

|

.068

|

.053

|

.188

|

.175

|

.115

|

.090

|

.030

|

2

|

|

12

|

.511

|

.487

|

.134

|

.118

|

.067

|

.056

|

.077

|

.061

|

.248

|

.235

|

.128

|

.103

|

.032

|

3

|

|

1/4

|

.573

|

.546

|

.150

|

.133

|

.075

|

.064

|

.087

|

.070

|

.263

|

.250

|

.143

|

.118

|

.033

|

3

|

|

5/16

|

.698

|

.666

|

.183

|

.162

|

.084

|

.072

|

.106

|

.085

|

.352

|

.339

|

.193

|

.168

|

.059

|

4

|

|

3/8

|

.823

|

.787

|

.215

|

.191

|

.094

|

.081

|

.124

|

.100

|

.383

|

.370

|

.226

|

.202

|

.063

|

4

|

| Grade | 18-8 Stainless Steel, 4.8, 8.8, A2, A4, A2-70; A4-70; A4-80 Machine Screws |

|---|---|

| Stainless Steel Screw standard | ISO 14583 |

| Stainless Steel counter sunk screws standard | ISO 10642 |

| British standards | BS 57 |

| Stainless Steel Machine Screws Size |

Stainless Steel Machine Screws M2, M3, (M3.5), M4, M5, M6, M8, M10, M12, (M14), M16, (M18), M20, (M22), M24, (M27), M30, M33, M36, M42, (M45), M48 to M160 and Custom Sizes |

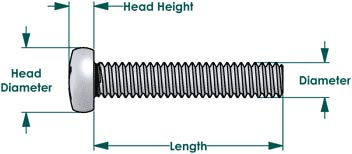

| Length | 3 mm to 200 mm |

| Stainless Steel Threads: | METRIC, BSW, BSF, UNC, UNF or as required |

| Standard: |

DIN, ISO, JIS, GB, IS, BS, ASTM and all International Standards |

| DIN Standard | B.S. DIN 933, DIN 931, DIN 934, DIN 912, DIN 603, DIN 6923, DIN 970, DIN 7981, DIN 7982, DIN916, DIN 913, DIN 7985 |

| UTS – Unified Thread Standard | UNC, UNF, UNEF, UNS, NPT, NPTF |

| Dimensions | ASME B18.6.3 **Exception: screws 6 inches and shorter are fully threaded. |

| Tolerance | +/-0.01mm to +/-0.05mm |

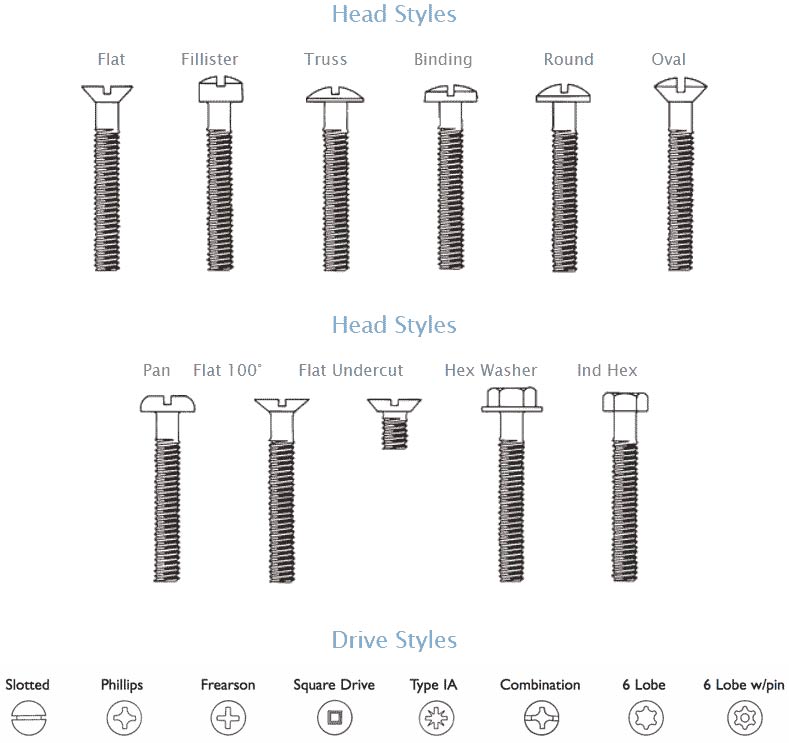

| Head drive: | Phillips, Slotted, Phillips/Slot, Six-Lobe, etc |

| Type | Pan/ Round/ Oval/ countersunk/ Truss head |

| Head | Pan head, flat head, oval head, hex head, phillips head |

| Finishing: | Zinc (yellow, white, blue, black), black oxide Geometry, Dacroment, anodizing, nickel plated, plated zinc-nickel, Stainless steel: Passivated Self-Colour, Hot Dip Galvanised (HDG), Bright Zinc Plated (BZP), Sherardized, Stainless Steel, Mechanically Applied coating and some special one like DACROMET |

| Finish | Per ASTM A380/A380M |

| Production process | Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing |

| Origin and service-region: | European Origin of Stainless Steel Machine Screws are Western European. However projects with eastern origin are possible on request. |

| Surface Coating: |

All surface finishes can be supplied, including Zinc, Galvanised, Sherardized, Electroless Nickel, Dacromet, Geomet & PTFE. |

| Surface treatment |

|

| Top Manufacturers | SPAX® Screws, GKW, Unbrako, Kundan, APL, Sundaram Precision, Infasco, EBY Fastener Etc. |

| Stainless Steel Machine Screws Packing: | IN BULK: canton, pallet, Small Boxs / carton / pallet, or customer request |

| Why choose us? |

|

| MOQ | 5 pieces |

| Test Certificate: |

|

| Free Samples | Yes |

| Delivery time | Regular product is about 7-15 days, custom product will according to special requirement |

| Payment Terms | T/T, Paypal, Western Union, L/C or Trade Assurance 30% deposit & balance before shipping |

| Other available material |

|

| Uses & application | Railway, Wind tower, Nuclear power, Automotive industry, Construction, Electronic industry |