ASME B16.11 is a standard that covers forged steel fittings, including socket-welding and threaded fittings. These fittings are used for high-pressure and high-temperature service in various industries, including oil and gas, chemical processing, power generation, and more. The standard defines the dimensions, tolerances, materials, marking, and testing requirements for these fittings.

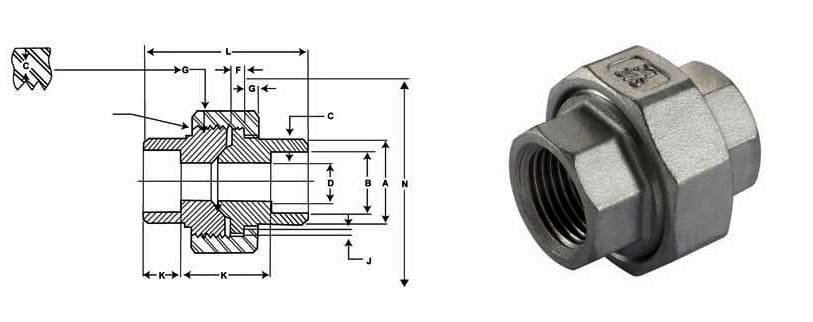

Types of Fittings : ASME B16.11 covers various types of forged steel fittings, including socket weld and threaded fittings. Common types include elbows, tees, couplings, unions, caps, and plugs, among others.

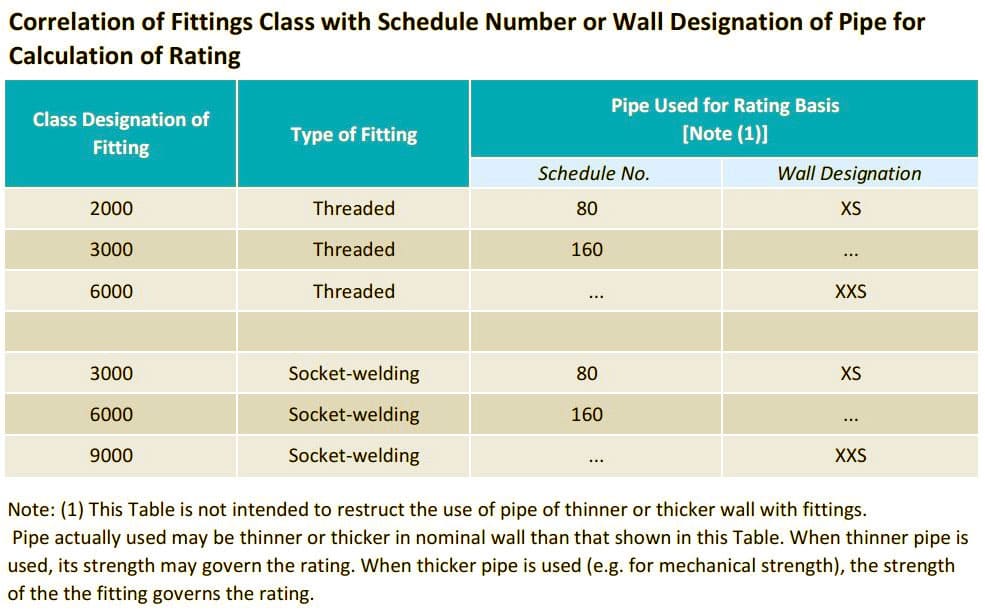

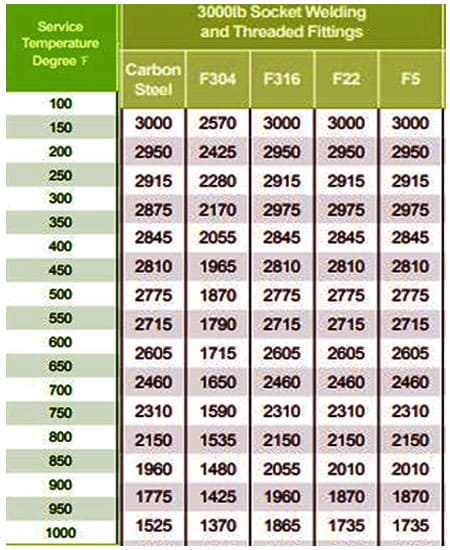

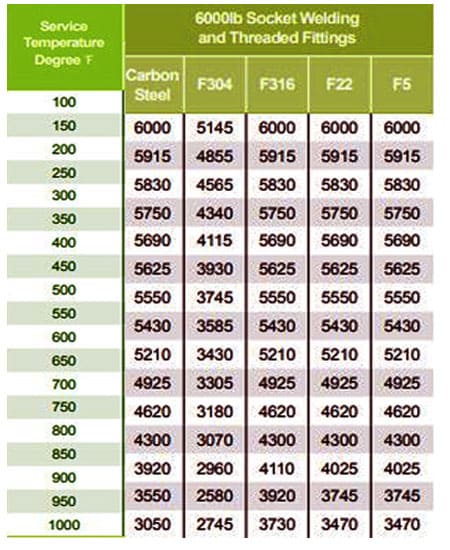

Pressure Ratings : The fittings are classified into different pressure classes, ranging from 2000 to 9000. These pressure classes indicate the maximum pressure the fittings can withstand at specific temperatures.

Materials : The standard specifies the materials for forged steel fittings, including carbon steel, alloy steel, and stainless steel. The material selection is based on the requirements of the specific application.

Size Range: : ASME B16.11 fittings are available in a range of sizes, and they are designed to match with pipes according to ASME B36.10 and ASME B36.19 specifications.

Threads : Threaded fittings are provided with tapered threads in accordance with ASME B1.20.1. The standard specifies the taper, pitch, and allowances for threads.

Socket Welding : Socket weld fittings have a socket at one end into which the pipe is inserted. The joint is then made by fillet welding the pipe to the fitting. The standard provides details on the dimensions and tolerances for socket weld fittings.

Marking : Fittings made in accordance with ASME B16.11 are required to be marked with specific information, including the manufacturer's name or trademark, material, size, and pressure class.

Testing : The standard outlines various testing procedures to ensure the quality and integrity of the fittings. Common tests include visual examination, dimensional inspection, and pressure testing.

Applications : ASME B16.11 fittings are widely used in piping systems where high-pressure and high-temperature conditions are present. They are suitable for applications in industries such as oil and gas, petrochemical, chemical processing, and power generation.

| Product Description | Pressure Class (#) | ||

|---|---|---|---|

| Class 2000 Fitting | Class 3000 Fitting | Class 6000 Fitting | |

| ASME B16.11 Elbow ASME B16.11 Tee/ ASME B16.11 Cross/ ASME B16.11 Coupling ASME B16.11 Bushing/ End Cap |

1/2 - 4" | 1/2 - 2" | 1/2 - 2" |

| 1/2 - 4" | 1/2 - 2" | 1/2 - 2" | |

| 1/2 - 4" | 1/2 - 2" | 1/2 - 2" | |

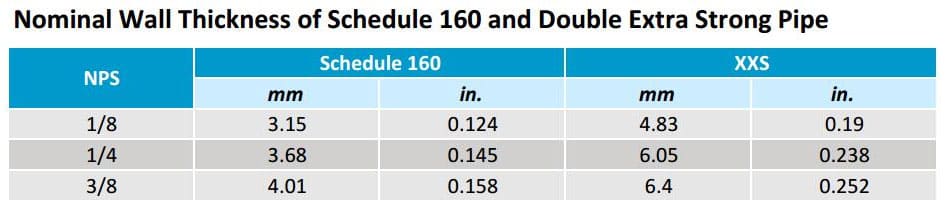

| Wall Thickness Of Steel Pipe | 80 Sch | 160 Sch | XXS |

| Specification Chart: | ASME B16.11 Fittings |

|---|---|

| Manufacturer Types | Elbow (45 Deg/ 90 Deg) Coupling (Full/ Half) Cross (Equal/ Reducing) Union (Male/Female), Outlet (Lateral/Branch) Tee (Equal/ Reducing) Threaded Pipe Cap Plug (Hex Head/ Square Head/ Round Head/ Bull) . |

| Method Types | Threaded (NPT) Socket Weld BSPT BSP |

| Type Of Standards | Bs3799 ASME B16.11 MSS SP 83 MSS SP 95 MSS SP 79 JIS B2302 |

| Manufacturer Size | SW Fitting = ½” Inch To 8” Inch Threaded (NPT) Fitting = ½” Inch To 8” Inch |

| Pressure Class | SW Fitting = Class 3000/ Class 6000/ Class 9000 NPT Fitting = Class 2000/ Class 3000/ Class 6000 |

| Production Technique | Forged/ Heat treated and machined |

| Our service | Nace Mr 01 75 Sour Service Impact Test As Per Ug 84 Macro Structure Analysis Hydrogen Induce Cracking Test (Hic) Sulphide Stress Cracking Test (Sscc) Cryogenic Services (Cryo),hydrogen Services (H2) Helieum Leak Test Dye Peniterant Test (Dp) Magnetic Partius Test (Mp) Post Weld Heat Treatment (Pwht) Ultrasonic Test (Ut) Hydro Test, Etc. |

| Application | Power/ gas/ petroleum/ chemical/ metallurgy/ shipbuilding etc. |

|

Nominal Diameter Of Steel Pipe

|

Outer Diameter |

Wall Thickness (WT) |

Socket Weld Bore |

Water way Bore |

Depth of Socket Weld |

Length Assem Nominal |

|||

|

(D) minimum

|

(C) minimum

|

(D1)

|

(D2)

|

(J) minimum

|

(L)

|

||||

|

DN

|

Nominal Size Of Steel Pipe

|

Socket (SW) |

Threaded (NPT)

|

Socket (SW)

|

Threaded (NPT)

|

Socket (SW)

|

Socket & Threaded |

Socket

|

Socket & Threaded

|

|

6

|

1/8

|

21.8

|

14.7

|

3.2

|

2.5

|

10.65

|

6.43

|

10

|

41.4

|

|

8

|

1/4

|

21.8

|

19.0

|

3.3

|

3.1

|

14.10

|

9.45

|

10

|

41.4

|

|

10

|

3/8

|

25.9

|

22.9

|

3.5

|

3.2

|

17.55

|

13.51

|

10

|

46.0

|

|

15

|

1/2

|

31.2

|

27.7

|

4.1

|

3.8

|

21.70

|

17.07

|

10

|

49.0

|

|

20

|

3/4

|

37.1

|

33.5

|

4.3

|

4.0

|

27.05

|

21.39

|

13

|

56.9

|

|

25

|

1

|

45.5

|

41.4

|

5.0

|

4.6

|

33.80

|

27.74

|

13

|

62.0

|

|

32

|

11/4

|

54.9

|

50.5

|

5.3

|

4.9

|

42.55

|

35.36

|

13

|

71.1

|

|

40

|

11/2

|

61.5

|

57.2

|

5.6

|

5.1

|

48.65

|

41.20

|

13 |

76.5

|

|

50

|

2

|

75.2

|

70.1

|

6.1

|

5.6

|

61.10

|

52.12

|

16

|

86.1

|

|

65

|

21/2

|

91.7

|

85.3

|

7.7

|

7.1

|

73.80

|

64.31

|

16

|

102.4

|

|

80

|

3

|

109.2

|

102.4

|

8.4

|

7.7

|

89.80

|

77.27

|

16

|

109.0

|

| Dimensions Of ASME B16.11 Fittings | Up to 2" (Size) NB | 2 1/2" & 3" (Size)NB | |

| • Bore Of Socket Weld | + 0.25 | + 0.38 | |

| - 0.00 | - 0.00 | ||

| • Body Bore | + 0.00 | + 0.00 | |

| - 1.52 | - 3.00 | ||

| A | 1/4" NB (Size) | ± 0.8 | ± 2.50 |

| 3/8" TO 3/4" NB (Size) | ± 1.6 | ||

| 1"T0 2"NB (Size) | ± 2.0 | ||

| Size Of Pipes In Inch | Dia Of (A) |

Dia. Of (B) |

ASME B16.11 Weight in Pounds |

|---|---|---|---|

| 1/8 | 0.69 | 0.66 | 0.06 |

| 1/4 | 0.80 | 0.80 | 0.10 |

| 3/8 | 0.94 | 0.97 | 0.15 |

| 1/2 | 1.11 | 1.17 | 0.22 |

| 3/4 | 1.24 | 1.38 | 0.32 |

| 1 | 1.43 | 1.74 | 0.52 |

| 1-1/4 | 1.72 | 2.07 | 0.76 |

| 1-1/2 | 1.87 | 2.36 | 0.99 |

| 2 | 2.25 | 2.86 | 1.49 |

| 2-1/2 | 2.68 | 3.57 | 2.78 |

| 3 | 3.05 | 4.23 | 4.41 |

| 4 | 3.72 | 5.24 | 6.72 |

| Description Of ASME B16.11 Pipe Fitting Size | Class Designation | ||

|---|---|---|---|

| Class 3000 Fitting | Class 6000 Fitting | Class 9000 Fitting | |

| Elbow (45 degree and 90 degree) ASME B16.11 Tee/ ASME B16.11 Cross/ (ASME B16.11 Full Coupling And Half Coupling) ASME B16.11 End Cap |

½ - 4 Inches | ½ - 2 Inches | ½ - 2 Inches |

| ½ - 4 Inches | ½ - 2 Inches | ½ - 2 Inches | |

| ½ - 4 Inches | ½ - 2 Inches | ½ - 2 Inches | |